Types of sterilizers

Sterilization guarantees the elimination of germs, including spores, causing infection.

All instruments must be packed and sterilized to ensure that they are sterile at the point of use.

The reference standards for steam sterilizers are:

a. EN 13060 that defines requirements for manufacturing small steam sterilizers.

According to this standard, sterilizers are divided into 3 types:

- Type N sterilizers, intended for the sterilization of non-wrapped solid products.

- Type S sterilizers, intended for the sterilization of products specified by the manufacturer of the sterilizer.

- Type B sterilizers, intended for the sterilization of all types of load, such as porous, solid and hollow instruments both wrapped and double-wrapped.

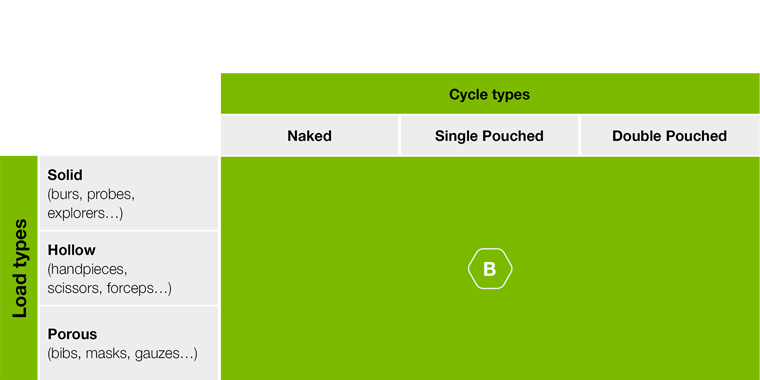

B Cycle

Type B sterilizers, intended for the sterilization of all types of load, such as porous, solid and hollow instruments both wrapped and double-wrapped.

S Cycle

Type S sterilizers, intended for the sterilization of products specified by the manufacturer of the sterilizer.

The manufacturer of the sterilizer has determined what a particular cycle of the sterilizer can be used for, and has specified that information for the user in the IFU.

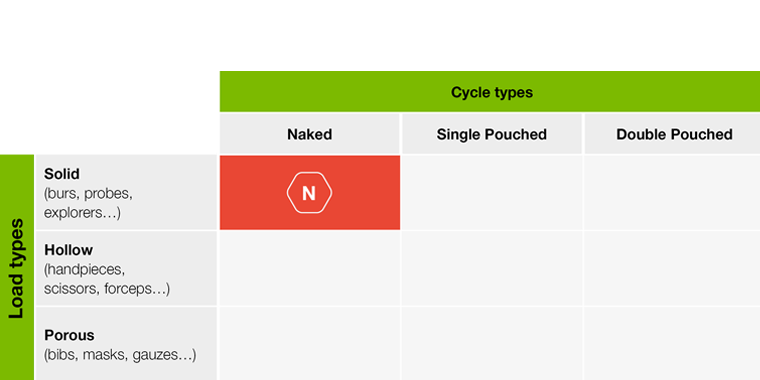

N Cycle

Type N sterilizers, intended for the sterilization of unwrapped solid instruments.

The N means None hollow and None wrapped (Naked solid items).

b. EN 285 that defines requirements for manufacturing big steam sterilizers.

c. ANSI/AAMI ST55 that is the North American standard for what concerns steam sterilization. According to this standard, sterilizers are divided into 2 types:

- gravity displacement

- dynamic air removal

Appropriate accessories

for full traceability

More scientific details

Learn more about professional sterilization.

Visit our recommended W&H AIMS workflow at aims.wh.com

*not available in North America