Benefits of Implantmed during implant treatment

“Technology, function and design are very impressive”

Dr. Karl-Ludwig Ackermann interview in which he spoke about W&H’s new Implantmed implantology motor.

Oral surgeon Dr Karl-Ludwig Ackermann has a practice in Filderstadt (Germany) and teaches implantology and aesthetic dentistry at two universities. He has placed several thousand implants over the last 38 years. Since autumn 2016, Dr Ackermann has been working with the new, enhanced implantology motor - Implantmed by W&H.

Easy to use, safe and cost-effective treatment

What is it like placing implants with the new Implantmed?

Dr. Ackermann: The unit is very impressive - both in the details and as a whole. I’d like to highlight the wireless foot control, which means it can be controlled without annoying cables. The new Implantmed can be superbly integrated in practical implantology owing to its dimensions and ergonomic design. In my opinion, the design is also very appealing.

What are its specific benefits?

Dr. Ackermann: W&H have introduced a whole series of technical features into the new Implantmed, such as the convenient instrument trays and the neat solution to the coolant supply with its very easily inserted tube. The dockable W&H Osstell ISQ module for measuring implant stability is another unique feature. With this it’s possible to determine the stability of an implant in addition to the insertion torque at any time. Among other things, this is important for choosing the safe loading time and makes prosthetic treatment easier to predict.

Easy to use, ...

Have there been improvements in its operation?

Dr. Ackermann: Menu navigation via the touch screen is very well thought-out. All the functions are easy to select. They can be adjusted quickly to each implant system used and to the preferred settings for specific treatments. This applies for up to six users which is a real benefit in a larger practice or hospital. All the patient- or implant-related data can be stored on data media. That puts those of us working in implantology on the safe side, forensically speaking.

As a manufacturer, W&H supplies not only surgical devices but also the surgical dental handpieces to go with them. Why are they important?

Dr. Ackermann: Instruments with a sterile supply of coolant are absolutely essential for safe treatment. The straight and contra-angle handpieces from W&H meet all the requirements in respect of treatment and hygiene. What’s more, the contra-angle handpiece WS-75 L for implantology with a 20:1 transmission ratio has a special, patented hexagon chucking system. Chuck and bur shank remain intact under high power transmission, such as when preparing the implant bed or screwing implants into dense bone. This avoids high repair costs.

... safe and cost-effective treatment

Are cost-effectiveness and efficiency part of the deal for you?

Dr. Ackermann: Yes, the extremely robust transmission technology contributes to working ergonomically and safely with the Implantmed and the connected auxiliary equipment. Of course, it also contributes to cost-efficiency. The following case study illustrates how useful the machine-specific characteristics, referred to previously, are during an implant-based restoration in the anterior maxilla. I also used the W&H Osstell ISQ module to measure implant stability.

Case study: single screw implants for a zirconium oxide bridge in the anterior maxilla

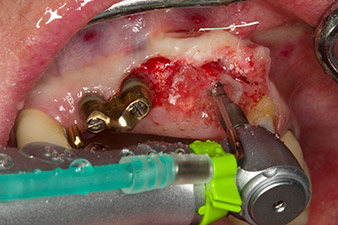

A 67-year old patient presented with endodontic problems and gingivitis around her prosthetic restoration in the maxilla. Teeth 21, 22, 23 carried splinted crowns which were connected to the implants at positions 12/11 via a precision attachment (see figure).

The plan was to place a zirconium oxide bridge on the existing implants at positions 12 and 11 and to place two new implants at positions 22 and 23. Implant placement and prosthetic restoration were to be carried out in stages and in combination with guided bone regeneration.

For the complete case report please click here:

Foto:

© Ackermann/Kirsch/Neuendorff

comments